Maximum energy efficiency through innovative substrate preheating

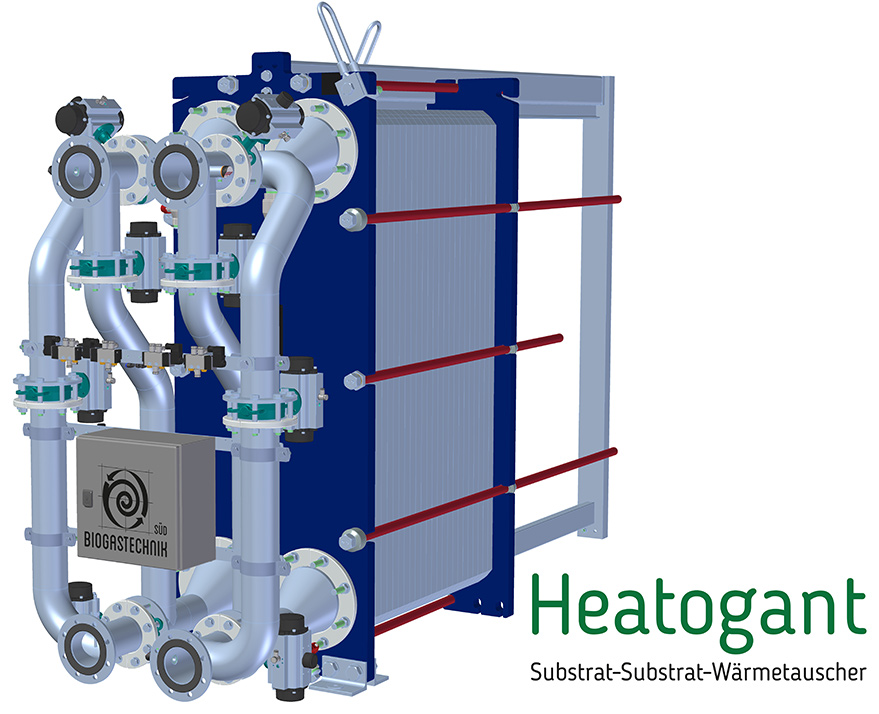

Heatogant

Substrate-substrate heat exchanger for biogas plants

Heatogant is the advanced substrate-substrate heat exchanger from Biogastechnik Süd GmbH, developed for efficient heat recovery in biogas plants. Particularly suitable for preheating liquid feedstock such as liquid manure or other residual materials, Heatogant uses the residual heat from fermentation residues and thus optimizes the energy efficiency of your biogas plant.

How does the Heatogant heat exchanger work?

The Heatogant combines a plate heat exchanger with an innovative switching mimicwhich enables optimum heat transfer. The warm fermentation residue heats cold liquid manure or other liquid feedstock before it enters the fermenter. This drastically reduces the energy required to heat the substrate , and heating is no longer a challenge even with large quantities of liquid manure.

To ensure maximum efficiency and trouble-free heat transfer, we recommend a particle size of <0 .5 mm in the heat exchanger. To achieve this, we rely on the proven separation with our SEPOGANT press screw separator. This ensures reliable separation of coarse components and significantly reduces the proportion of solids in the liquid substrate. This not only guarantees the functionality of the Heatogant, but also reduces wear to a minimum – for long-term stable and efficient operation.

The advantages of a biogas substrate - substrate heat exchanger at a glance

High heat transfer

Plate heat exchanger technology is significantly more efficient than conventional pipe systems.

Optimum fermenter temperature

Prevents temperature fluctuations due to the cold slurry supply.

Automatic cleaning

The switching mimic prevents extreme deposits such as sand, fibers or, if necessary, struvite and ensures trouble-free operation of the heat exchanger.

Lower emissions

Lowered storage temperatures (<30°C in the slurry store) minimize the emission of ammonia and other pollutants. This results in lower emissions for the substrate at the end of the process.

Energy saving

No additional heating energy required for slurry preheating.

Low maintenance

The alternating flow directions effectively prevent clogging of the channels in the heat exchanger system, which reduces maintenance work to a minimum. The Heatogant can therefore be described as largely self-cleaning.