OPTIMISED & USER FRIENDLY SOLUTIONS

SEPOFARM MODULE

Press screw separator

The solution for dairy farmers

Our Sepofarm Module separation technology is based on the traditional process of manure separation. Sepofarm Module was developed to increase the applicability and usability of separation, especially for agricultural enterprises.

The problem & the solution

Too little space, too much slurry! Many agricultural enterprises have problems with proper nutrient management. The nitrogen and phosphorus balance often does not add up, as too much of both must not be applied to the land. In addition, nutrients are lost through ammonia emissions if no spreading close to the soil is possible. The modular Sepofarm Module separator, which consists of a separator and an easily transportable container (hook lift), allows the farmer to process the slurry on their farm without long storage times and to use the fresh solids in biogas plants. Until now, this was impossible to this extent, as the separators were usually firmly tied in one place and transporting the digestate proved to be difficult without a container especially for this purpose. This approach allows the release of some of the phosphate via the solid phase that is produced during separation. This allows farms to achieve efficient nutrient management.

The separation of slurry also makes it possible to produce litter. This is an interesting alternative to conventional variants, such as a straw mattress, especially for dairy farmers.

The process

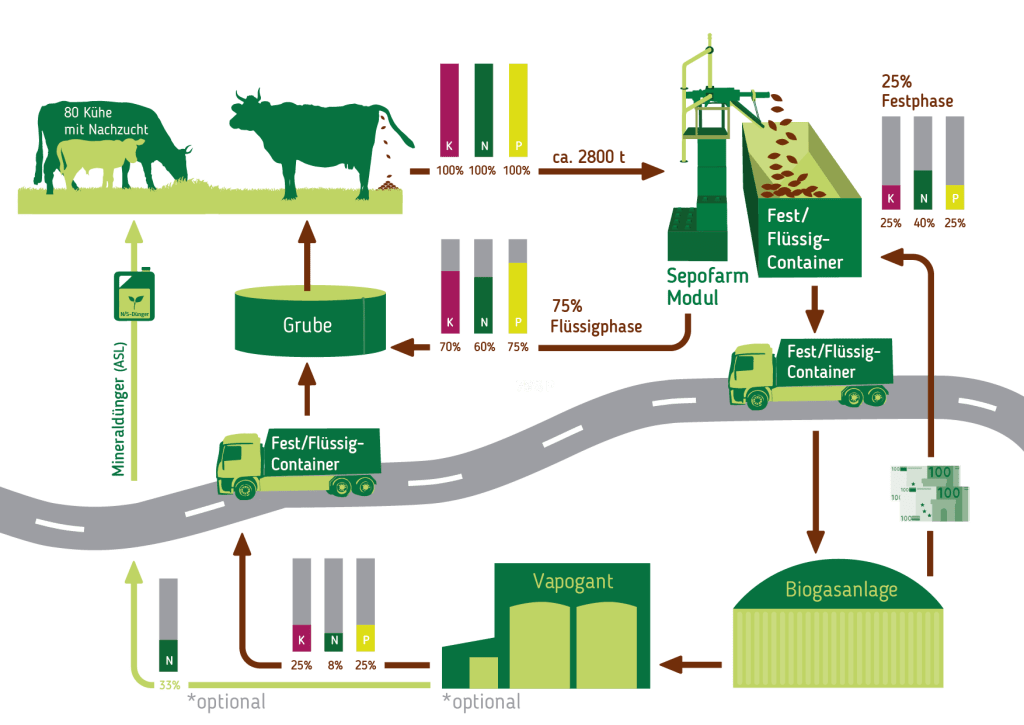

In a first step, the slurry produced in livestock farming is pumped into the Sepogant screw press separator. Here, the solids (approx. 25 %) are separated from the liquid portion (approx. 75 %) in the slurry. The liquid phase is discharged into the pit and the solids can be easily transported to another location using a solid/liquid container developed for this purpose in particular. This allows transporting the solid portion to a biogas plant, for example, and at the same time taking back solid or liquid substrate via the return transport.

BENEFITS OF SEPOFARM MODULE

FOR CONVENTIONAL AND ORGANIC FARMS

- generally all benefits of the Sepogant

- cost savings for straw when solid material is used as bedding for cubicles

- cost savings for slurry store agitator

- cost savings for slurry store construction

- cost savings for using a trailing hose instead of a trailing shoe distributor

- reduced nitrogen losses due to application close to the ground

- saving water for dilution

Cooperation with Sepofarm Module

Biogas plant operators

- separated manure from slurry as a substitute for maize

- reduced footprint

- greater selection of potential cooperation partners

- optimised nutrient management

Dairy farmers

- efficiency increase through separation

- up to 25 % storage reduction

- substrate supplier for biogas plants

- reduced footprint

- optimised spreading

- solution to nutrient problems

- CO2 neutral production

- reduced emissions

Sepofarm Module and Vapogant

- in-house mineral fertiliser production (ASS)

- much more efficient use of nitrogen

- optimised nutrient management

- reduction in the transport and storage volume through digestate enhancement

- lower investment in digestate store

In a nutshell

Separation allows agricultural enterprises to increase their benefit, reduce storage, and thus save space. In addition, the liquid phase of the digestate can be optimised and spread close to the ground. The isolation of the solids, which contain about 20-30 % of the phosphorus, solves the nutrient problem as well. In return, biogas plant operators can replace maize and renewable raw materials in biogas plants by taking up the pressed solids (manure). This means they do not have to cultivate it and can save on land and emissions. In addition, this model offers a large selection of possible cooperation partners. Ultimately, both agricultural enterprises and biogas plant operators can benefit from the use of Sepofarm Module and the thus resulting circular economy – a win-win situation.

Nutrient cycle of the future

factfeeder

Sepofarm Module is an innovative technology. It is easy and cost-efficient to install. Contact our sales department to learn whether Sepofarm Module is economical for you.