Maximum mixing - High reliability - Low maintenance

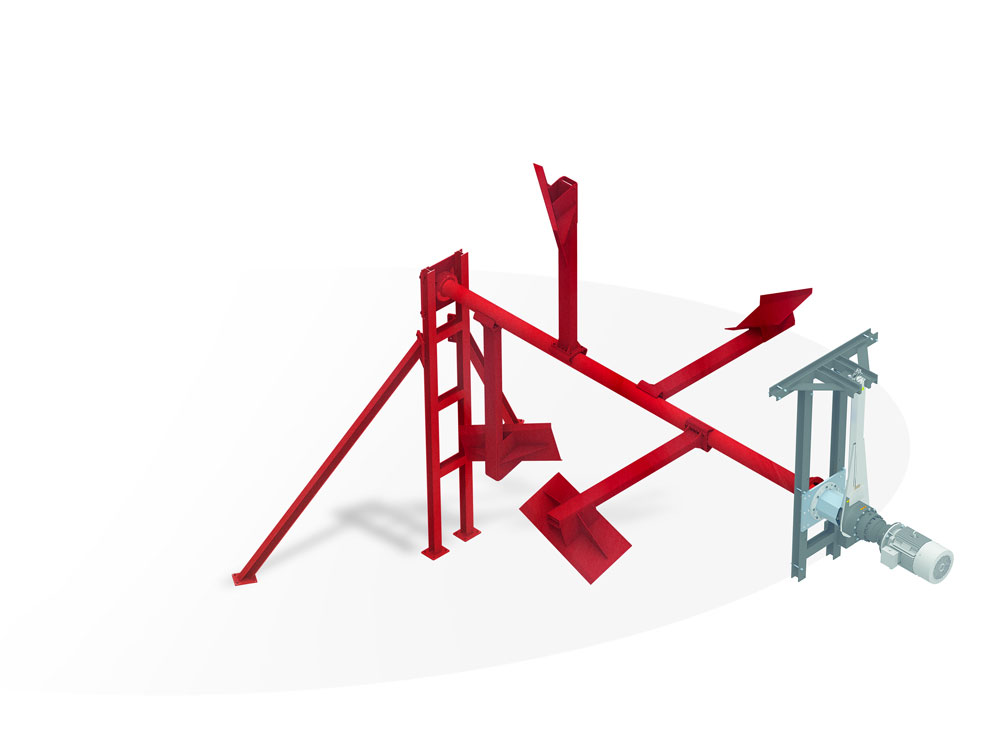

Varibull paddle agitator

Varibull - the efficient paddle agitator for biogas plants

The Varibull paddle agitator is the ideal solution for efficient and energy-optimized mixing in fermenters, secondary fermenters and fermentation residue stores. With technology proven a thousand times over, it ensures homogeneous distribution of slurry, manure and renewable raw materials, even with high dry matter contents.

- Powerful and efficient: Four specially arranged paddles ensure fast and complete mixing over a large vertical area.

- Durable and low-maintenance: External drive unit for easy maintenance, robust mechanical seal and wear-free plain bearing inside.

- Optimum operational safety: Developed in accordance with the highest safety standards and harmonized standards in accordance with the Machinery Directive 2006/42/EC.

- Flexible use: Suitable for substrates with up to 15 % dry matter, pH values of 6-8 and temperatures up to +55 °C.

Agitation systems for biogas plants

Varibull Long-wave agitator

Paddle agitatorVaribull L (RT-PRW-L)

The Varibull L is a powerful long-shaft agitator with a 10-metre-long agitator shaft, which has been specially developed for the homogeneous mixing of fermentation substrates in large-volume fermenters. It is ideal for use in tanks with a diameter of 30 metres or more, regardless of whether they are made of concrete or steel. Thanks to its robust construction and efficient stirring technology, the Varibull L ensures optimum substrate mixing, even under demanding conditions.

Varibull Ex

Safe stirring in potentially explosive atmospheres

The Varibull is the most widely used paddle agitator among the slow-running long axle agitators for biogas plants. Optionally also available as an explosion-proof version.

For biogas plants with special safety requirements, we offer the Varibull paddle agitator in an explosion-proof version. This version has been specially developed for use in potentially explosive atmospheres and meets the highest safety and efficiency standards.

Technical highlights of the explosion-proof version:

Powerful drive:

-

- 15 kW

- Explosion-proof motor for high safety with consistent efficiency

Maximum security inside:

- Varibull mixing technology paddle agitator, complete in explosion-proof design

- Special plastic storage, explosion-proof storage

This EX-certified agitator technology ensures safe, efficient and durable operation – even in demanding environments with explosive gas mixtures.

Varibull Ex – your partner for safe and efficient agitation in hazardous areas!

Efficient, robust and sustainable:

The

Original*

Paddle agitator for optimum biogas production.

- Energy-efficient mixing for biogas plants

- Robust agitator blades for long-lasting performance

- Ideal for fibrous substrates such as grass silage and liquid manure

- Reduces energy consumption and wear on the system

- Promotes microbiology in the fermenter for high gas yields

- Low maintenance thanks to robust technology

*The original paddle agitator is and remains Made in Germany

BENEFITS OF THE PADDLE AGITATOR

Varibull

- Ideal for the anaerobic digestion of renewable raw materials, in particular grass silage and manure as well as other substrates

- Energy-efficient thanks to large-surface stirring paddles

- Thorough mixing across the different substrate layers while being gentle on the bacteria

- Reliable operation also with high dry-matter content and long-fibred substrates

- Maintenance-free sealing of the wall

- Maintenance-free and durable plain bearing inside the pit

- No height adjustment inside the digester

- Also handles varying filling levels

- No additional mechanical parts, such as chains, ropes or other suspension gear

- Simply install, switch on and stir – That’s all!

Paddle agitators in biogas plants - Advantages and applications - Frequently asked questions (FAQ)

A paddle agitator ensures uniform mixing of the process liquids and contributes to the homogenization of the suspension in biogas plants. This optimizes microbial activity and increases biogas production. The effective flow pattern and suitable paddle geometry make the fermentation process more efficient, resulting in a better methane yield.

A paddle agitator is particularly suitable for energy-efficient mixing in biogas plants. Thanks to the robust agitator blades and the right speed, it requires less power to mix large quantities of substrate evenly. This reduces operating costs and improves the energy efficiency of the biogas plant.

Yes, paddle agitators are specially developed for processing fiber-rich substrates such as grass silage, corn silage or manure. They prevent blockages and ensure uniform mixing, which optimizes gas production and methane production. The paddle geometry is designed to work well even at high viscosities.

The paddle agitator’s effective stirring technology ensures that the substrates are mixed quickly and evenly. This shortens stirring times, which optimizes energy consumption and makes gas production more efficient.

A paddle agitator can also work reliably in biogas plants with fluctuating fill levels, as it distributes the substrate evenly. This ensures constant microbial activity and consistent gas production, even with a high dry matter content.

Thanks to the robust drive technology and maintenance-free slide bearings, the paddle agitator requires little maintenance. It has a long service life and is characterized by low maintenance costs, which improves the operational efficiency of the biogas plant.

Yes, paddle agitators can be easily retrofitted to existing biogas plants. They are compatible with various types of fermenters, whether steel or concrete tanks. This enables cost-effective and quick retrofitting.

The paddle agitator ensures even mixing and prevents foaming, which improves the gas quality in the biogas plant. It maximizes methane production and ensures higher gas production.

What are the main differences between a rod agitator and a paddle agitator in biogas plants?

Rod agitators work with a vertical agitating movement and are often suitable for deep fermenters. However, they offer a lower mixing effect with fibrous substrates or high viscosities. Paddle agitators with a horizontal agitating movement provide uniform mixing of the substrates, even with fluctuating fill levels, which makes them ideal for biogas production.

Paddle agitators are more energy-efficient due to their agitator technology and effective paddle geometry. They require less power and are ideal for biogas plants to reduce energy consumption. Rod agitators require more energy for high viscosities or difficult substrates and are therefore less energy efficient.

Paddle agitators are much better suited to fibrous substrates such as maize silage or manure. They prevent blockages and ensure a uniform mixture, whereas rod agitators often have problems with high viscosities and fibrous materials.

Thanks to their robust drive technology and maintenance-free plain bearings, paddle agitators require less maintenance. They have a long service life and incur lower maintenance costs. Rod agitators, on the other hand, often require regular maintenance as they are more susceptible to mechanical faults.

Paddle agitators offer a high degree of flexibility and are suitable for different types of substrate. They also work at high fill levels and can compensate for fluctuating substrate conditions. Rod agitators are less flexible and are only suitable for certain applications, especially with homogeneous liquids.

The paddle agitator ensures uniform mixing of the process liquids, which optimizes microbial activity and therefore methane production. Better homogenization of the suspension leads to stable gas production, while rod agitators are less efficient with heterogeneous substrates.

Paddle agitators require less maintenance due to their robust design and low susceptibility to wear. Rod agitators are often more expensive to maintain as they require more spare parts and often cause problems with difficult substrates.

Paddle agitators are more suitable for large fermenters, as they cope well with high substrate volumes and fluctuating fill levels. The agitator technology ensures even distribution and higher gas production, which is often not the case with rod agitators.

Paddle agitators are cheaper in the long term as they use less energy and require less maintenance. Rod agitators have higher operating and maintenance costs, especially when used in difficult applications.

The Varibull agitator is based on the same proven technology as the Paddle Giant, which was originally developed by us. While other manufacturers have moved their production abroad, we continue to manufacture the Varibull agitator in Germany. This enables us to ensure consistently high quality and durable workmanship. We have also further developed some aspects of the design to enable even more efficient mixing and a longer service life.

In a nutshell

The paddle agitator ensures energy-efficient and gentle mixing of the substrate thanks to its large agitator blades and optimum flow control. As a result, the biomass remains homogeneously distributed, deposits are prevented and the microbiology in the fermenter is ideally supported.

Thanks to the gentle but effective mixing, fibrous materials such as grass silage and other highly viscous substrates are optimally digested, which can increase the gas yield. At the same time, the efficient mixing technology reduces energy consumption and wear on the system.