OPTIMISED & USER FRIENDLY SOLUTIONS

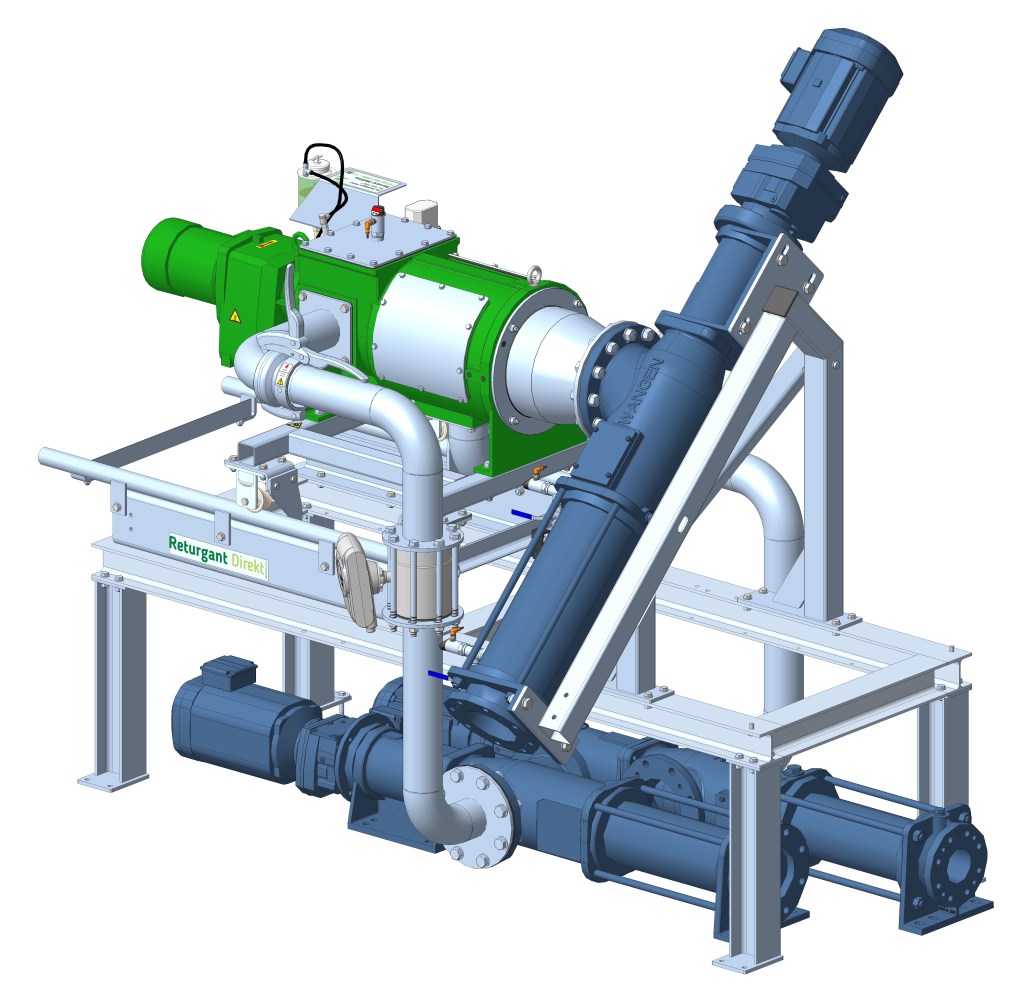

Returgant Direkt

The biomass return filter of the fermentation product line

The Returgant Direkt acts as a filter by returning unfermented fibers back into the system in a controlled manner. This ensures the stability of the entire system and increases the efficiency of the substrate, as feed is saved.

The problem & the solution

In the biogas industry, the reduction of emissions and the fact that the fermentation process takes place in a closed cycle play a decisive role. But how is it possible to achieve a smooth, emission-free and closed cycle in a biogas plant?

An innovative solution for this is to return the biomass through the Returgant Direkt biomass return filter.

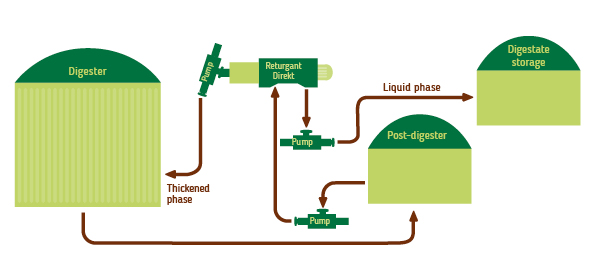

This biomass return filter can be integrated into the biogas plant in different ways and is thus integrated into a holistic cycle.

The process

The Returgant Direkt biomass return filter removes substrate from the fermenter or secondary fermenter and returns it directly after filtering with the thickened phase and the not yet fully fermented fibrous materials. The material that is not yet fully fermented (fiber >0.5 mm) is returned to the fermenter / secondary fermenter and has time to ferment further – because different feedstocks take different lengths of time to ferment.

The recycling of fibrous materials selectively extends the dwell time of the fibrous materials. This specifically retains fibrous matter and significantly reduces the proportion of non-fermented components in the fermentation product. The substrate is thus better fermented, which results in savings on substrate and a reduction in costs and the volume of fermentation products. In addition, removing the fibers makes the fermentation product more fluid, which makes it easier to spread and reduces the need for agitation in the fermentation product store.

The fiber-rich container contents stimulate the overall biology to break them down in a targeted manner. As a result, the material contains more poorly degradable components with the same feed, which requires the microorganisms to adapt in order to degrade them more efficiently. This improves the degradation rate for poorly degradable substances such as GPS (straw, manure), while the degradation rate for easily degradable substances remains unchanged.

Optionally, both an impurity separator and an ultrasonic system with the Returgant Direct can be embedded in the circuit. This helps to ensure that even more dry matter in the substrate can be broken down into biogas.

Integration of the Returgant Direkt with thick substrate pump

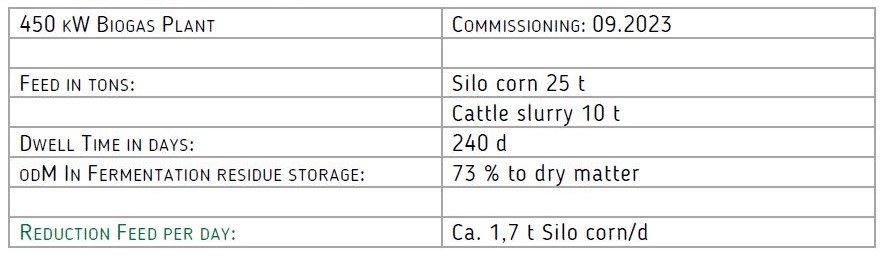

Higher biogas yield through more efficient fermentation

Advantages of Returgant Direkt

- BAFA funding possible

- Recycling of nutrient-rich substrates

- Optimization of the dwell time

- Reduced substrate requirement

- Preservation of valuable microorganisms

- Higher utilization of the gas potential by 5% – 20%

- No ammonia losses and additional costs for transportation/storage

- Substrate savings, due to complete substrate utilization

- Separation of foreign substances (including plastics) from the biogas cycle

- Saving of fermentation residue storage volume

- Saving on agitators in the digestate store

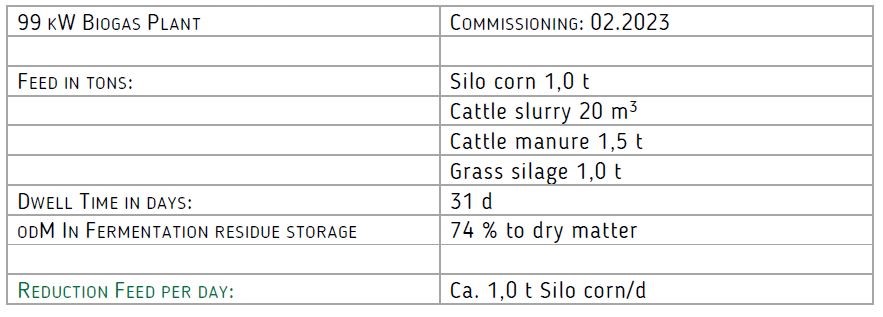

System examples

In a nutshell

The Returgant Direkt biomass recirculation filter offers an innovative solution by extending the retention time of fibrous materials and thus improving the degradation of poorly degradable substances. This leads to a more efficient and stable fermentation process, reduces costs and saves feed.