The thermal substrate optimisation system for maximum efficiency

OptiHeat

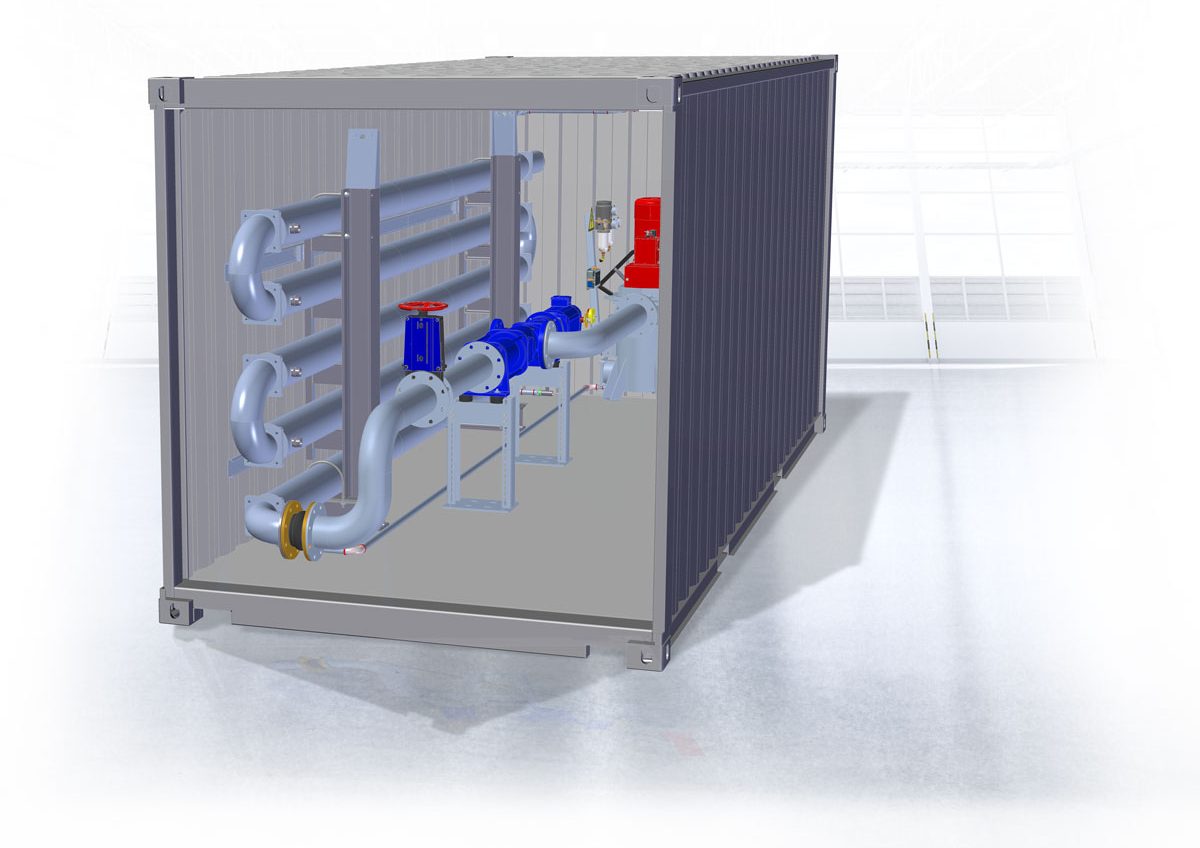

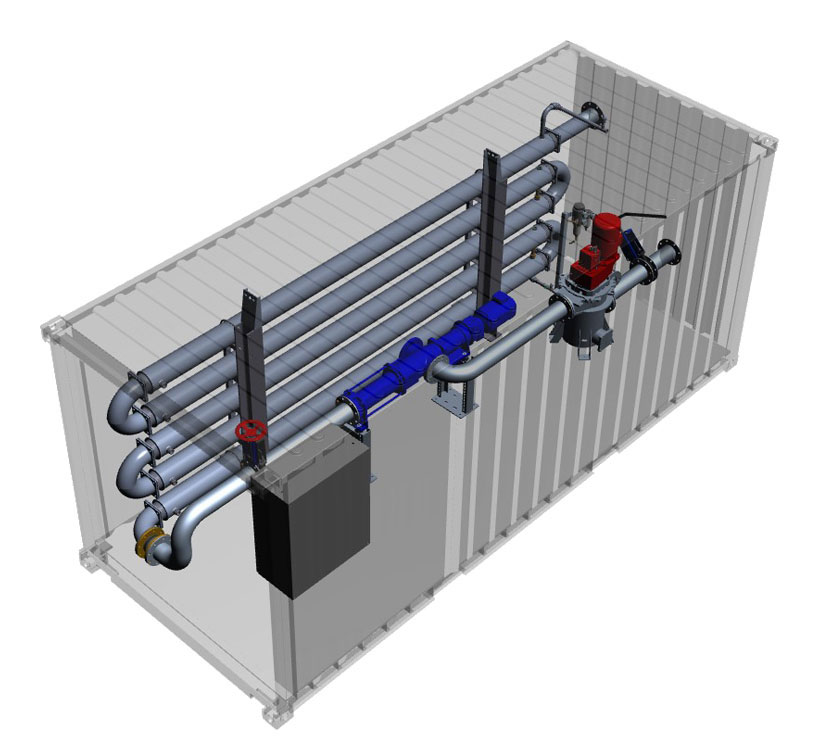

Pumping, shredding, heating the turnkey OptiHeat product bundle in a container

The fermentation temperature is crucial for the performance of a biogas plant. Many plants struggle with fluctuating temperatures, especially in the winter months, or are unable to optimally utilise substrates that are difficult to ferment due to technical limitations.

With OptiHeat, our product bundle in a container, Biogastechnik Süd GmbH offers a powerful solution for thermal substrate optimization. The substrate treatment system combines the advantages of the HeatCrack heat exchanger with a Vogelsang RotaCut wet shredder to efficiently treat substrates and maximize biogas production.

Thanks to intelligent heat utilisation, mechanical substrate preparation and sophisticated pump technology from Wangen Pumpen, the gas production is increased, the process stability is improved and the fermentation of even difficult substrates is optimised – without extensive modifications or control system adaptations.

Challenges in biogas plants - OptiHeat as solution

Heating problems and inefficient use of heat

- Worn or too small heating circuits lead to insufficient heat supply.

- Thermophilic system operation (50-55 °C) is often not feasible as the existing heating is not sufficient.

OptiHeat ensures targeted heat supply and enables more stable fermenter temperatures - even with thermophilic operation.

Drop in fermentation temperature in winter

- In many plants, the temperature drops to 32 °C in winter, which slows down microbial decomposition.

- Fluctuations between thermophilic and mesophilic reduce the gas production over several weeks per year.

With OptiHeat, the fermenter temperature remains stable - for optimum biological processes all year round.

Future use of substrates that are difficult to ferment

- The use of fibre-rich or poorly degradable materials such as solid manure, grass silage or manure with a high fibre content reduces gas production.

- A larger surface area for microorganisms to attack improves the degradation performance and increases the gas production.

The integrated Vogelsang RotaCut heavy material separator in the OptiHeat container shreds the substrate and improves fermentation.

No space required for additional technology or complex conversions

- Additional components in the pump rooms usually require complicated installations and control adaptations.

- There is often not enough space for larger heating systems or treatment units.

OptiHeat is a turnkey container solution that can be installed without interfering with existing control systems or conversions.

How does OptiHeat work?

1. Heat exchanger HeatCrack for targeted temperature adjustment

OptiHeat uses the HeatCrack heat exchanger to heat the substrate to the desired temperature.

- Heating by up to 10 °C for optimum fermenter temperatures

- Thermophilic (50-55 °C) or mesophilic (35-40 °C) operating mode possible

- Efficient heat recovery reduces heating costs

2. Mechanical substrate preparation with the Vogelsang RotaCut

The integrated Vogelsang RotaCut wet shredder ensures fine shredding of the substrates and protects the pump technology at the same time.

- Better gas production due to finer substrate structure

- Higher degradation rate of substrates that are difficult to ferment

- Foreign matter separator protects pumps and system technology

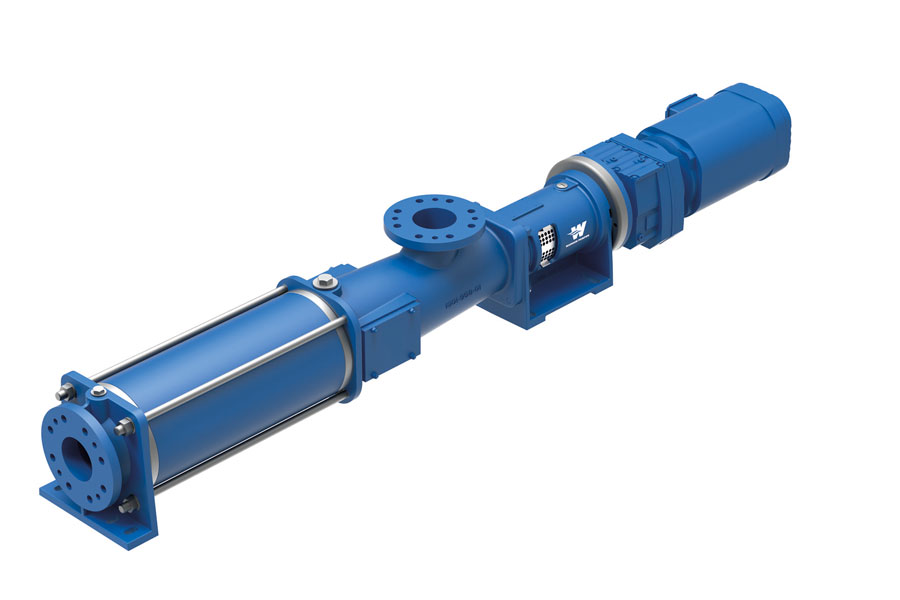

3. Pump technology from Wangen Pumps for optimum distribution

After heating and shredding, the substrate is pumped or returned to the fermenter using high-performance pump technology from Wangen Pumps.

- Optimum mixing and distribution in the fermenter

- Stable process control even with fluctuating feed-in quantities

4. Perfect addition to separation

- Pump protection thanks to integrated foreign body separator: Prevents damage and blockages, ensures operation.

- Can be used flexibly for various substrates: Ideal for slurry, manure, silage, fiber-rich materials.

- Process stability for better biology: Constant temperatures in the fermenter – ideal for microorganisms.

- For maximum efficiency, we recommend combining OptiHeat with our Sepogant press screw separator for optimum solid-liquid separation and with the Returgant to further reduce the residual volume.

The advantages of OptiHeat at a glance

Maximum fermentation efficiency

Fermentation temperature remains stable, even in winter.

Higher gas production

Better degradation rate thanks to mechanical substrate treatment.

Lower heating costs

Efficient heat recovery reduces energy consumption.

Field-proven technology with low maintenance and servicing costs

Already successfully in use in biogas plants for over 20 years.

Turnkey product bundle in a container

Consisting of the HeatCrack heat exchanger, a RotaCut wet shredder from Vogelsang, a pump from Wangen Pumpen and a Siemens control unit.

Pump protection thanks to integrated foreign matter separator

Prevents damage and blockages, safeguards operation.

Can be used flexibly for different substrates

Ideal for manure, dung, silage, fibre-rich materials..

Process stability for better biology

Constant temperatures in the fermenter - ideal for microorganisms.

Can be perfectly combined with our separation technology

Ideally complements Sepogant and Returgant for economical substrate processing.

Flexible use – three variants for every system

OptiHeat can be integrated at various points in the biogas process:

- Variant 1 – Maintaining/increasing the temperature

- Heat transfer: 30 – 50 kW

- Extraction: digester/post-digester

- Return: digester/post-digesterRecirculation: Fermenter/post-digester

- Variant 2 – Heating digestate store

- Heat transfer: 30 – 50 kW

- Extraction: digester/post-digester (end of the biological process)

- Return: digestate storeorage

- Variant 3 – Preheating

- Heat transfer: 50 – 70 kW

- Extraction: pre-pit

- Return: digester (start of the biological process)

Frequently asked questions about the OptiHeat system for biogas plants (FAQ)

Yes! OptiHeat is a flexible solution that can be integrated into existing and new plants.

OptiHeat combines heat exchange with wet shredding, which significantly increases efficiency.

Thanks to efficient heat recovery and robust technology, operating costs/m3 are minimal.

Yes! OptiHeat enables an increased substrate temperature, which supports thermophilic operation.

As a containerised solution, OptiHeat can be easily retrofitted without extensive modifications.

In a nutshell

OptiHeat – substrate treatment in a container

The compact system for thermal substrate optimization: heating, shredding, pumping – all in one container. For more stable processes, higher gas yields and reliable technology, even with demanding substrates.