OPTIMISED & USER FRIENDLY SOLUTIONS

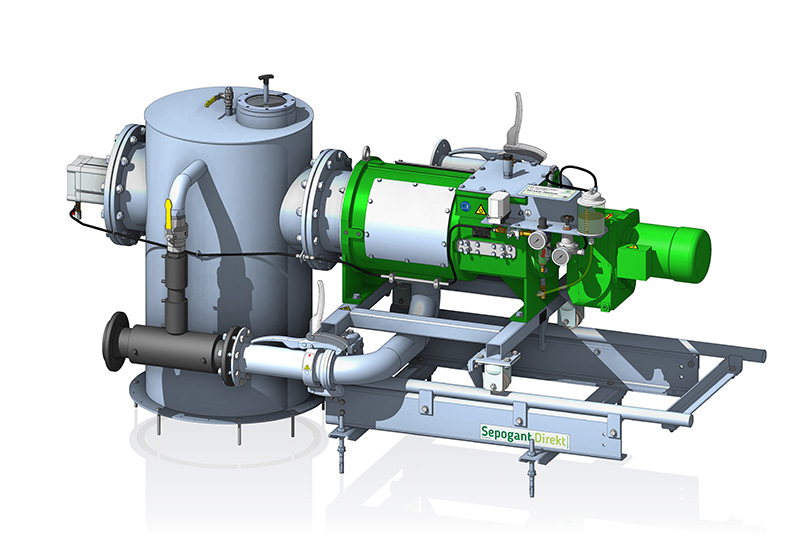

sepogant direct

The fermentation product separation cycle

Separation in its original form extended by the possibility of keeping digestate in a closed emission-free cycle – this is possible with the Sepogant Direct biomass recirculation filter!

The problem & the solution

Due to the new provisions of TA-Luft, the separation and storage of digestate is only permitted in closed rooms or under cover. This new regulation poses a major challenge for many farms.

The Sepogant Direkt press screw separator is the solution to this limitation. This special separator can be integrated into the biogas plant in different ways and is thus integrated into a holistic cycle.

We are rethinking separation: the Sepogant Direkt separates within the fermentation section!

The process

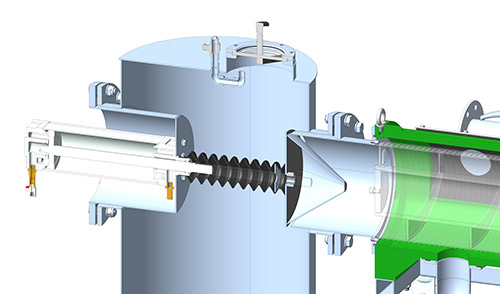

The Sepogant Direkt removes substrate from the fermenter or secondary fermenter in order to return it directly after separation with the pressed phase and the not yet fully fermented fibrous materials. The material that is not yet fully fermented (fiber >0.5 mm) is returned to the fermenter / secondary fermenter and has time to ferment further – because different feedstocks take different lengths of time to ferment.

With the Sepogant Direct, it is no longer necessary to collect the solid phase and feed it again regularly using the feeding technique, as is already successfully implemented in practice. This has the advantage that there are no additional emissions that occur outdoors, as the Sepogant Direkt technology is a closed system.

In addition, working time is saved and there is no need for transportation between the place where the pressed solid material is located and the fermentation container (e.g. fermenter). This results in further emission and cost savings, which would be caused by transportation or interim storage.

We only bring out liquid

Advantages of Sepogant Direkt

- Closed & emission-free slurry and digestate separation cycle

- Higher utilization of the gas potential by 5% – 10%

- No ammonia losses and additional costs for transportation/storage

- Substrate savings, due to complete substrate utilization

- Saving of fermentation residue storage volume

- Saving on agitators in the digestate store

In a nutshell

It is possible to achieve a smooth and emission-free cycle of fermentation product and manure separation embedded in a biogas plant by ensuring that the substrate, once in the fermentation cycle, never leaves this cycle again. This can be ensured by the separation technology of the Sepogant Direkt, as the separation of the input materials takes place in a closed system and the solid phase is not discharged as before, but can be conveyed directly back into the biogas plant.

The Sepogant Direkt can be easily integrated into the existing system. Process heat can also be saved in the fermenter.

This means that the cycle remains closed even with fermentation product and manure separation.